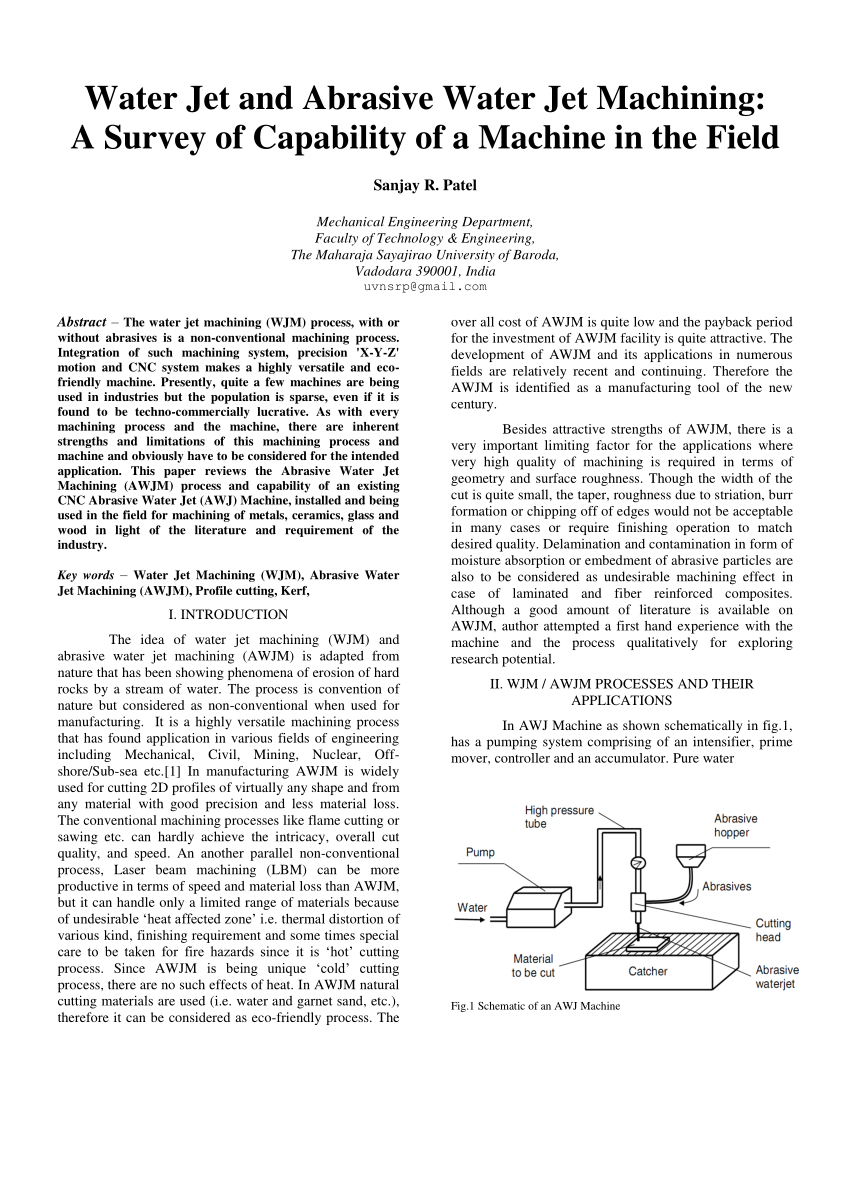

This paper presents a study conducted to determine the effect of abrasive waterjet awj and laser beam lb cutting technologies on surface roughness r a and micro hardness µ hv of the carbon steel samples in this article there is a brief discussion of the different ways of cutting carbon steel such as awj cutting as well as lb cutting.

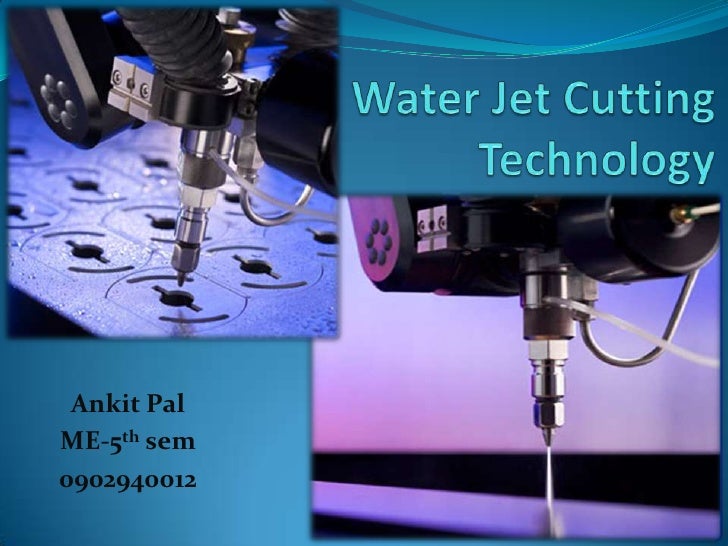

Water jet cutting technology abstract.

The term abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or granite while the terms pure waterjet and water.

The paper presents aspects regarding an innovative nonconventional technology abrasive water jet machining.

Fuzzy ahp based decision support system for technology selection in abrasive water jet cutting processes.

Also explore the seminar topics paper on waterjet cutting with abstract or synopsis documentation on advantages and disadvantages base paper presentation slides for ieee final year mechanical engineering me or production automobile students for the year 2019 2020.

The present study is aiming at designing a deep sea abrasive water jet cutting system and executive instrument for core.

This study tried to compare two cutting technologies with respect to their technical operational aspects.

Explore waterjet cutting with free download of seminar report and ppt in pdf and doc format.

Use of water jet has been in.

Water jet cutting a technology on the rise october 2010 page 7 5.

Water jet cutting was f ound to be a.

A water jet cutter also known as a water jet or waterjet is an industrial tool capable of cutting a wide variety of materials using a very high pressure jet of water or a mixture of water and an abrasive substance.

Prediction of distribution relationship of titanium surface topography created by abrasive waterjet.

Tehnički vjesnik technical gazette 18 2 187 191.

Technology same water jet cutting is so safe that we can use it to cutting food.

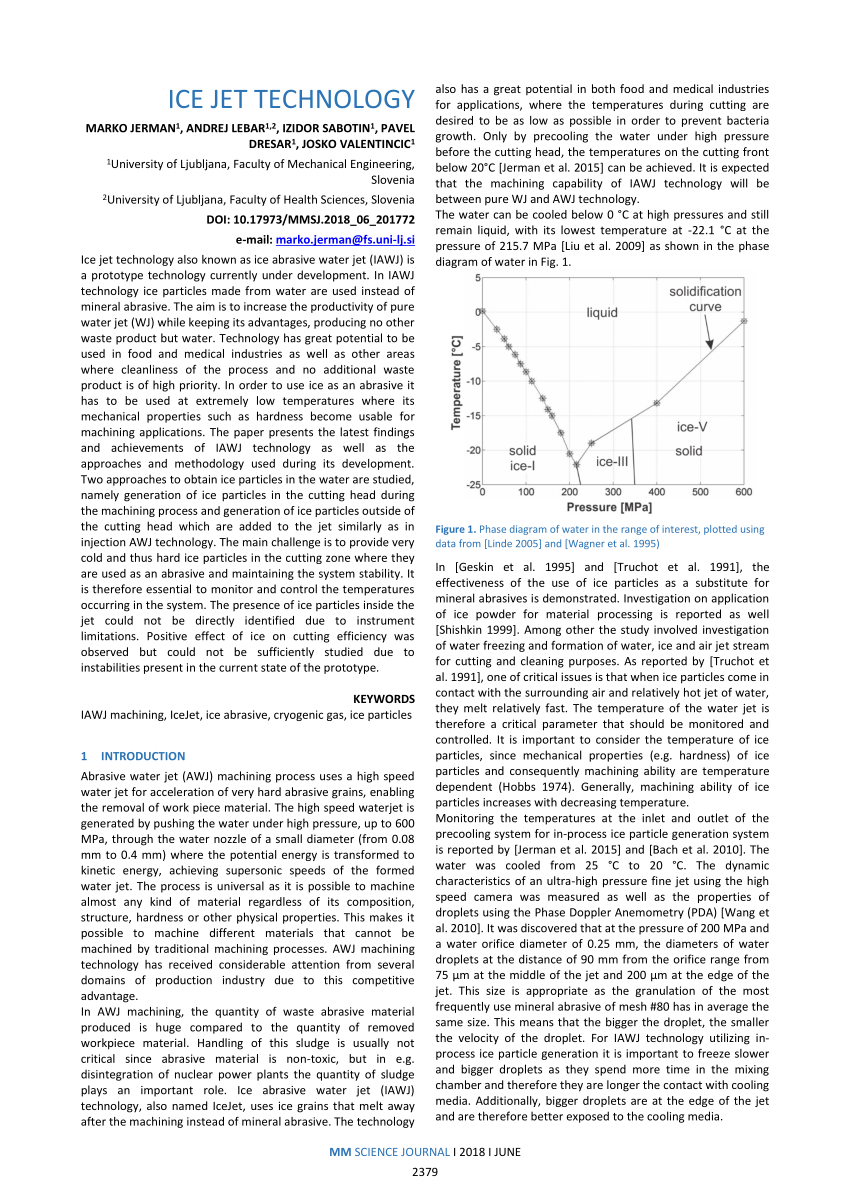

Ultra high pressure abrasive water jet cutting is a new technology device in salvage ocean development military fields and it also is one of the hottest and most advanced topics in the field of fluid control.

9 hloch s valíček j.

The main objective of this paper is to select the best technology for cutting metal.

Pure water cutting pure waterjet is used mainly for relatively soft materials such as plastic textiles paper sealing materials metalic foils.

Design of experiment and evaluation of abrasive waterjet cutting in titanium alloy sheet 2015 design of experiment and evaluation of abrasive waterjet cutting in titanium alloy sheet diploma work in the master programme materials engineering.

Two types of cutting let us take a closer look at the basics of the two waterjet cutting methods.

The search of ornamental rocks cutting technology to meet the market and efficiently together economic environmental and safety parameters is increasingly requested in the mineral sector.

Chalmers university of technology abstract.