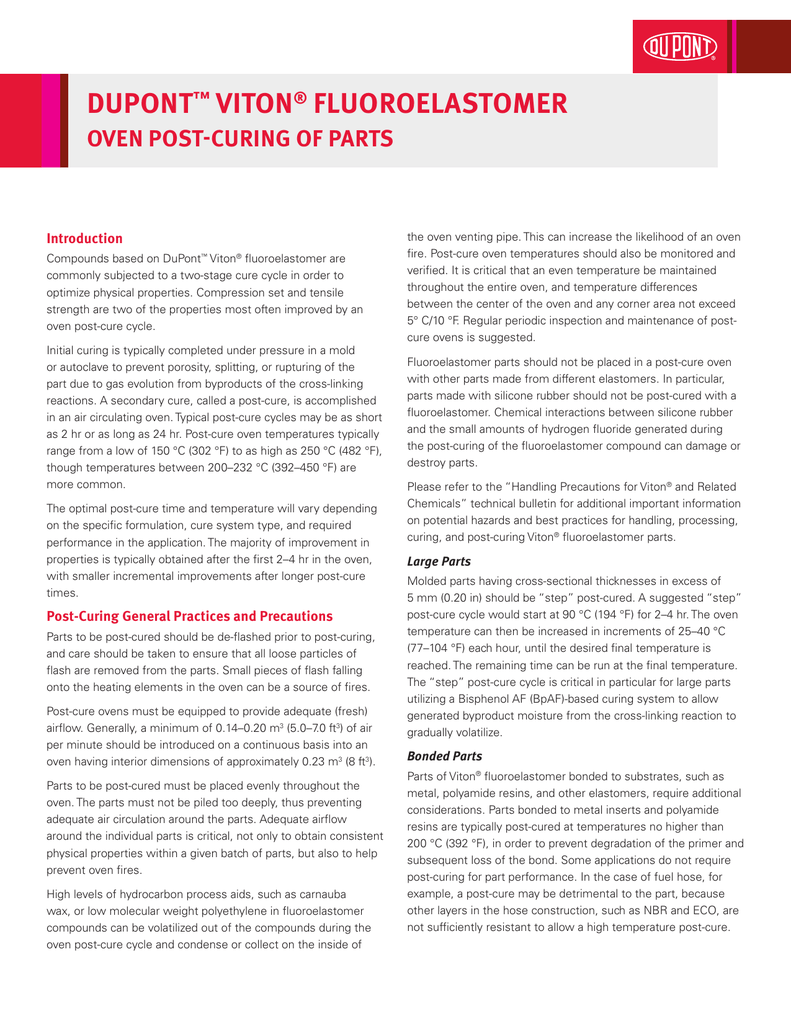

A fully equipped elastomeric laboratory is available to recommend and develop a proprietary rubber compound formulation for our customers from any of the synthetic elastomers that are in the marketplace today including fluoroelastomers our forte.

Viton rubber compound formulation.

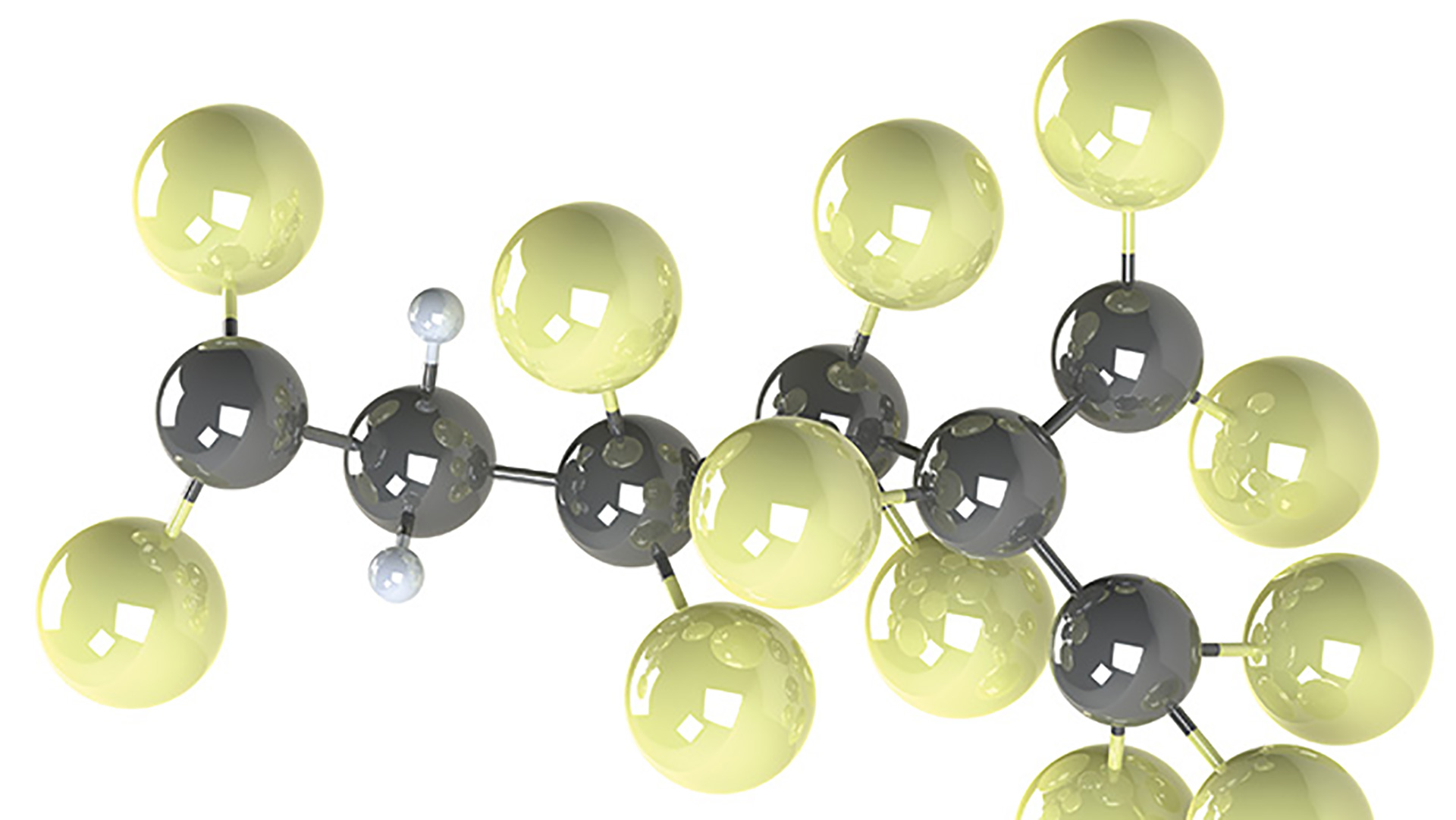

3m dyneon fluoroelastomer fe 5640q is a 66 fluorine dipolymer of vinyline fluoride and hexafluoropropylene.

With better chemical resistance than stan dard viton a compound 51414 how ever with a slightly higher compres sion set.

Hp xl and mgo elastomag.

Fluorocarbon elastomers exhibit excellent resistance to high temperature and low compression set.

Viton glt introduced in 1976 was the first commer cial fluoroelastomer to use this fluorinated vinyl ether monomer.

They respond very well with resistance to ozone high temperatures oxygen mineral oil synthetic hydraulic fluids fuels aromatics and many organic solvents and chemicals over a temperature range of 25 f to 400 f.

V 141 based on genuine viton gf.

The very basic character of any amine initiates dehydrofluorination at a vinylidene fluoride vf2 site now followed by an amine addition crosslink.

Ucured fkm rubber compound.

A design of experiments doe was run using fe 5640q varying the levels of carbon black mt n990 ca oh 2.

Products made with viton fluoroelastomers retain their flexibility shape and seal when exposed to chemicals and high temperatures.

Viton freeflow extrusion process aids also improve processing increase output and reduce waste.

These are starting point rubber compounding formulations for providing guide lines only and should be confirmed by laboratory trials.

Fluoroelastomers can withstand various harsh environments.

Viton rubber compound formulation for fkm oil seal.

The subsequent hydrogen fluoride hf molecule reacts with magnesium oxide a compounding ingredient rearranging to form magnesium fluoride and water.

This compound offers the best chemical resistance of all types belonging to the standard viton families.

Viton gflt like viton glt exhibits significantly improved low.

The polymer selection and compounding ingredients should be considered carefully for.

It is expected that modifications may be necessary to produce satisfactory commercial products.

Customized viton rubber formulation for fkm oil seal.